Ladias Tasos1, Karvounidis Theo2, Georgopoulos Kostas3 ladiastas@gmail.com, tkarv@unipi.gr, kgeorgop@gmail.com

1 PhD in Computer Science, Physicist, former School Counsellor

2 Dr. Computer Science Teacher, University of Piraeus

3 Dr. of Natural Sciences, H.E.D., H.E.D., University of Ioannina

SUMMARY

In dealing with Engineering Systems it was found that on the one hand there were different

names for the same type of gear and that the same name was used for different gears. These created the need for a clear vocabulary based on a categorisation of gears. The first division of gears into categories was made by looking at their anatomy on the one hand and the ways in which they were combined on the other. As far as anatomy is concerned, this is subdivided into subcategories dealing with the type of movement of the gear (rotating-sliding, convex-hollow, circular or non-circular, central or eccentric axis) and the arrangement of the dentition on the periphery (spur gears, crowns, straight or oblique threading, covering the periphery with teeth). The categorisation based on the ways in which they are combined to transfer motion is considered both in relation to the axes of rotation of two combined gears (gears with a common axis or parallel/perpendicular axes or oblique axes such as spiral, hypoid, helical, spiral, endless screw) and the way in which motion is transferred by means of a connection between them. The latter yields two subcategories with the transfer of motion being carried out by intermeshing or non-intermeshing gears. Here the roles played by gears such as guides, followers, meso gears, micro gears, the types of gears (linear and epicyclic) and the outputs of the motion including the differential are mentioned. Finally, the transfer of motion without gears involved is achieved by using a bracket, chain, etc.

KEYWORDS: Granada, STEM

INTRODUCTION

The involvement of writers during the quarantine period in the translation and

editing four volumes for the introduction to Engineering Systems for young students was the need and the trigger for a deeper engagement with gears. An additional motivation was Papert’s (1992) references to “The Gears of My Childhood” with which he begins his book “Mental Storms”.

In dealing with Mechanical Systems it was found that on the one hand there were different names for the same type of gear and on the other hand that the same name was used for different gears. These created the need for a clear vocabulary based on a categorisation of gears. This categorisation was initially based, on the one hand, on the structural anatomy of the different gears and, on the other hand, on the different ways in which they functioned and the linkages they used to transmit motion.

(A) LOCATION OF GRAINS

In this context a further categorization of the gears based on the

anatomy was based on the type of movement and the arrangement of their dentition.

(A.1) Based on their type of movement, grenades can be divided into (rotating) and sliding grenades.

(A.1.I) The (rotating) gears are considered to be the absolute majority. Their anatomy is determined by factors such as (a) in which position the

denture, (b) the shape of its cross-section that is perpendicular to the axis of rotation, and (c) the position of this axis in the plane of the cross-section.

(A.1.I.a) The position of the denture can be on the outer perimeter of the gear (convex gear), on the inner side of the perimeter (concave gear) or both (Figure 1).

Figure 1: Categorization of gears according to the position of the denture.

(A.1.I.b) As regards the shape of the cross-section of the gear perpendicular to its axis of rotation, it can be either circular (disc, cylinder and cone) or non-circular (Figure 2). The cage gear and the screw gear or worm gear also belong to the group of cylindrical gears.

Figure 2: Classification of gears according to their cross-sectional shape.

(A.1.I.c) As regards the position of the axis of rotation in the plane of the gear cross-section, this can be either from the centre or off-centre (eccentric gear) (Figure 3).

Figure 3: The axis of rotation can pass through the centre or be a cam gear.

(A.1.II) Apart from (rotating) gears, the sliding (straight) rack can also be considered as a gear, taking for granted that “the gear is a wheel with teeth on its circumference” (Hutcheson & Haas, 2021) and that the straight section is an arc of a circle with an infinite radius (Figure 4).

Figure 4: Examples of a toothed beam in the role of a sliding gear.

(A.2) Veneers based on the arrangement of their dentition. The factors that characterize the dentition of the gears are (a) the angle of the tooth axis, (b) the angle of the spline with respect to the axis of the rotation carrier, and (c) the degree to which the periphery is covered with teeth.

(A.2.I) The angle of the tooth axis can be referred to either in relation to the radius and can be conjugate or oblique (Figure 5 left), or in relation to the plane of the cross-section and can be on the plane like the spur gear or perpendicular to the plane (spur gear-crown) as shown in Figure 5 right.

Figure 5: Examples of gears with different angles of the tooth axis.

(A.2.II) Based on the angle of the thread in relation to the axis of the rotation carrier, we can have a straight gear (straight) or helical/skewed gear (skewed), as shown in

Figure 6. Bevels can be single thread or double thread (herringbone) Also the direction of the bevel gears is determined by the right hand or left hand rule.

Figure 7: Examples of gears with different threads.

(A.2.III) Regarding the degree of coverage of the periphery with teeth, there can be full coverage or partial coverage (Figure 7). Partial coverage may have many or few teeth, one tooth or no tooth that the gear is considered to degenerate into a wheel/pulley.

Figure 7: Examples of gears with different degrees of tooth coverage around their circumference.

(B) GRAIN CONNECTIONS

The categorization of gears based on the ways in which they are combined for

motion transfer will be considered both in relation to the axes of rotation of two mating (adjacent) gears and the way in which motion is transferred through a linkage between them.

(B.1) Regarding the position of the axes of rotation, two gears can have either a common axis of rotation or different axes of rotation which can be parallel, perpendicular or lateral (Figure 8). When the axes are parallel they may be conjugate or there may be a common axis creating compound gears. Vertical axes can either belong to the same plane or be incompatible.

Figure 8: Different positions of the gear rotation axes.

A memorable case of gears with perpendicular axes (coincident and incompatible) is the bevel gears as shown in Figure 9a. These gears may have a straight (Figure 9b) or helical (Figures 9c and 9d) thread and their shafts may be co-planar (Figures 9b and 9c) or misaligned (Figure 9d). In more detail, gears that have helical threads and are connected obliquely according to their position (Eitel, 2020) are called spiral, hypoid, spiroid, while tangential gears are called endless screws as shown in Figure 9e.

Figure 9: Examples of gears connected obliquely.

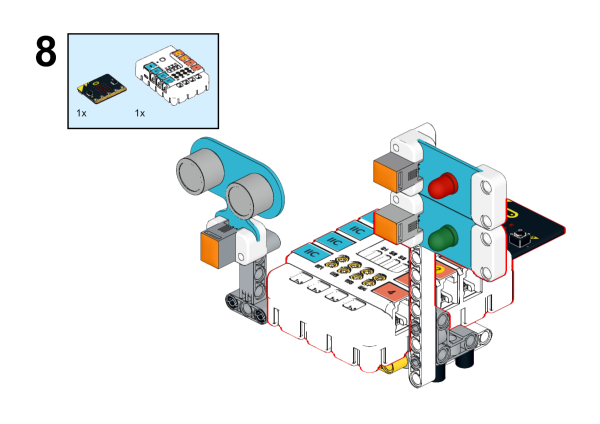

(B.2) For the transfer of motion through gears, linkages are used in which the gears may or may not be meshing. Examples of motion transfer with such linkages are shown in Figure 10.

Figure 10: Drive transfer with engaged and disengaged gear linkages.

(B.2.I) Intermeshing gears in interconnections (gear systems) can be classified into three categories depending on (a) the role played by the gears in the interconnection (b) the type of interconnection and (c) the number of outputs of the interconnection drive.

(B.2.I.a) Depending on the role played by a gear in the gearing, it is considered as a guide gear, follower gear or idler gear (Figure 11).

Figure 11: Gear designations according to their role in the interconnections.

The term (drive) micro gear / pinion is also used to describe the input gear of the drive in an interconnect or in a subsystem of the interconnect (Figure 12).

Figure 12: Examples of pinion gears playing the role of the driving gear.

(B.2.I.b) Gear train assemblies (gear systems) can be linear or helical gear trains as shown in Figure 13. Linear gear trains may be simple (when consisting of simple gears) or complex (when including complex gears) or may be arranged in such a way that they reverse the direction of motion. Examples of epicyclic gears are the harmonic gear and various types of planetary systems.

Figure 13: Examples of linear and cyclical gear series.

(B.2.I.c) Depending on the number of outputs of the drive, gear linkages can be divided into those that have one output, several outputs or alternative outputs (differential) as shown in the examples in Figure 14.

Figure 14: Examples of single-output, three-output and differential gear linkages with alternative outputs.

(B.2.II) For the transfer of motion outside the meshing gears, they can be connected with arms, chains, toothed belts and crawlers (Figure 15).

Figure 15: Examples of fasteners with non-meshed gears.

OPINION

Based on the proposed categorization of gears, we believe that students

can have a guide that will allow them to identify both the anatomy of a gear and the role it plays in a linkage (gear system) for the transfer of motion. This identification will enable students to understand the existing names of gears.

An important problem that arises when translating the nomenclature of gears into Greek is the coexistence of names with a completely different style, such as the terms endless screw and worm gear that refer to the same type of gear. Also the proposed rendering of established English terms in Greek (pinion as micro gear, idler as meso gear, hub as interface gear) is left to be confirmed in practice through the process of natural selection of the relevant memes.

A future prospect for research is to develop this categorization into a classification geared towards teaching gears in the context of STEM education based on the SOLO taxonomy.

REFERENCES

Eitel Lisa (October 7, 2011 – updated February 2020). What are gears for power transmission?

Technical summary for design engineers. Retrieved 4 July 2022 from

https://www.motioncontroltips.com/what-is-a-gear/.

Hutcheson, B. & Haas, P. (2021). Engineering Systems 3 / Student’s Book, Athens, Greece: Publications.

STEM Education (ISBN: 978-618-85470-0-1) Papert, S. (1991).